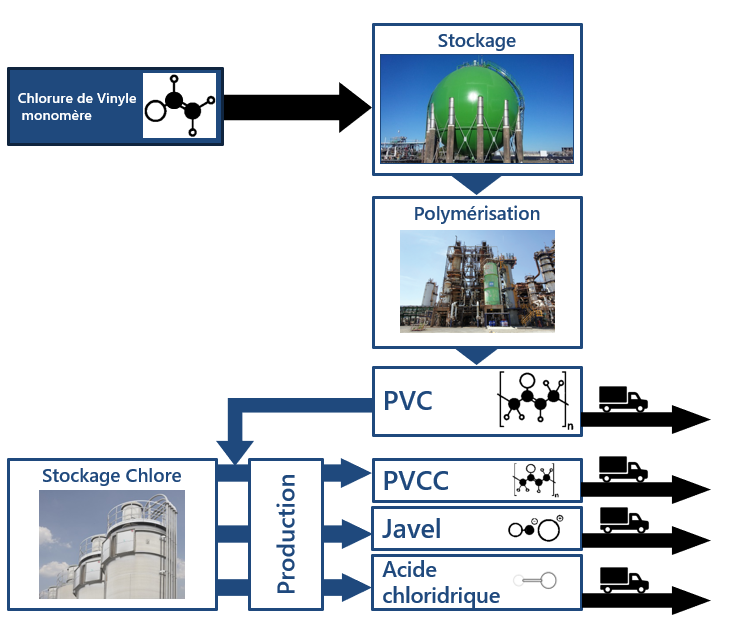

1. Can you introduce yourself & present your missions/daily life before COVID-19?  My name is Alexandre, I have been working as a consulting engineer at Abylsen for almost a year. I work for a large industrial client that converts vinyl chloride (CV) into polyvinyl chloride (PVC) in order to supply its own customers with raw materials. I am responsible for the regulatory aspect of everything that will affect lifting equipment or all the devices that will be used to handle heavy loads (overhead cranes, trolleys …) I am in charge of checking that all the regulatory elements (documents & others) are up to date and, if not, I take care of planning the interventions in order to correct the defects / shortcomings. It is a mission with a strong transversal responsibility that allows me to evolve on a daily basis both with the teams in charge of production and the teams in charge of equipment maintenance. I also have a complementary activity on a daily basis: I am on a project to rehabilitate all the monorail lifting equipment on the site. 2. Can you tell us about your customer's core business My customer receives CVM in the form of gas by boat directly on site and then transforms it into PVC (in powder form).

My name is Alexandre, I have been working as a consulting engineer at Abylsen for almost a year. I work for a large industrial client that converts vinyl chloride (CV) into polyvinyl chloride (PVC) in order to supply its own customers with raw materials. I am responsible for the regulatory aspect of everything that will affect lifting equipment or all the devices that will be used to handle heavy loads (overhead cranes, trolleys …) I am in charge of checking that all the regulatory elements (documents & others) are up to date and, if not, I take care of planning the interventions in order to correct the defects / shortcomings. It is a mission with a strong transversal responsibility that allows me to evolve on a daily basis both with the teams in charge of production and the teams in charge of equipment maintenance. I also have a complementary activity on a daily basis: I am on a project to rehabilitate all the monorail lifting equipment on the site. 2. Can you tell us about your customer's core business My customer receives CVM in the form of gas by boat directly on site and then transforms it into PVC (in powder form).  The transformed PVC is then either delivered as is to their customers or it is transformed directly into PVCC with Chlorine. The latter allows the production of bleach and hydrochloric acid. 3. How has the Coronavirus crisis impacted your daily life? Of course, COVID has drastically changed the way we work with far fewer staff (production teams have been divided by 2 since the beginning of the crisis) and very strict health regulations to respect (wearing gloves, masks, safety distance …) Overall, the production rate remains very high on our site as PVCC is used, for example, to manufacture hospital medical equipment. We also continue to produce a lot of bleach to make it available to hospitals that need it. In short, we must produce just as much (if not more) with teams & therefore reduced resources which pushes us to gain in efficiency & to change our ways of working.

The transformed PVC is then either delivered as is to their customers or it is transformed directly into PVCC with Chlorine. The latter allows the production of bleach and hydrochloric acid. 3. How has the Coronavirus crisis impacted your daily life? Of course, COVID has drastically changed the way we work with far fewer staff (production teams have been divided by 2 since the beginning of the crisis) and very strict health regulations to respect (wearing gloves, masks, safety distance …) Overall, the production rate remains very high on our site as PVCC is used, for example, to manufacture hospital medical equipment. We also continue to produce a lot of bleach to make it available to hospitals that need it. In short, we must produce just as much (if not more) with teams & therefore reduced resources which pushes us to gain in efficiency & to change our ways of working.

1. Can you introduce yourself & your missions/your daily routine before COVID-19? My name is Alexandre, I have been working as a consulting engineer at Abylsen for almost a year. I work for a large industrial customer who transforms vinyl chloride (VCM) into polyvinyl chloride (PVC) in order to supply its own customers with raw materials. I am responsible for the regulatory aspect of everything that will affect lifting equipment, i.e. all the equipment used to transport heavy loads (overhead cranes, trolleys, etc.). I am in charge of checking that all the regulatory elements (documents & other) are up to date and, if not, I take care of planning the interventions in order to correct the defects/malfunctions. This is a mission with a strong cross-disciplinary responsibility that allows me to evolve on a daily basis with the teams in charge of production as well as the teams in charge of equipment maintenance. I also have a complementary day-to-day activity: I'm working on a project to overhaul all the site's monorail lifting equipment. 2. Can you tell us about your customer's core business? My client receives CVs in the form of gas by ship directly on site and then converts them into PCV (in liquid form). The processed PVC is then either delivered to their customers as is or we process it directly on site into other materials such as bleach or CPVC. 3. How has the Coronavirus crisis impacted your daily life? Obviously, COVID has drastically changed our way of working with much less staff (production teams have been halved since the beginning of the crisis) and very strict health regulations to be respected (wearing gloves, masks, safety distance…). Overall, the production rate remains very high at our site since CPVC is used, for example, to manufacture the bags in which the plasma is recovered from the donors. We also continue to produce a lot of bleach to make it available to hospitals that need it. In short, we have to produce just as much (if not more) with smaller teams & therefore fewer resources, which pushes us to become more efficient & to change our ways of working.